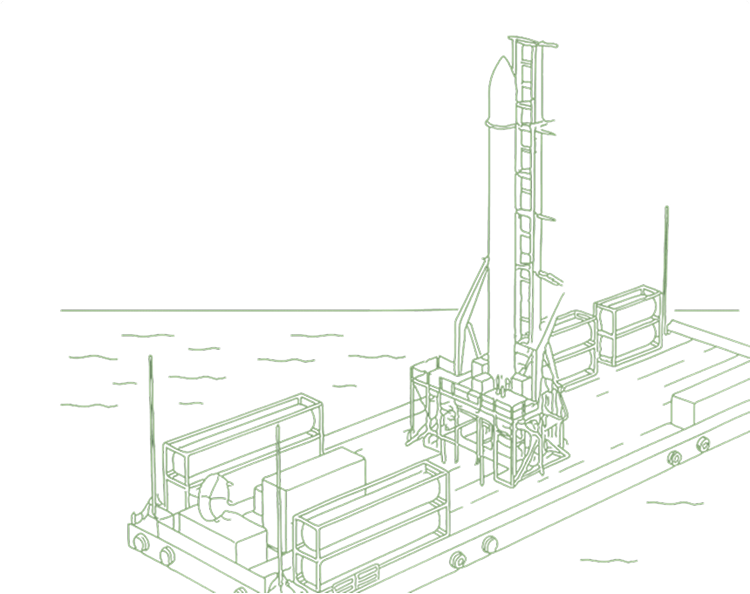

Flexible, profitable, multi-services

-

Versions compatible with stage testing and combined tests.

-

Business model analysis to reduce at maximum operational expenditures and make the facility profitable.

-

We provide the full range of services, from site selection, operation and processes management to maintenance.

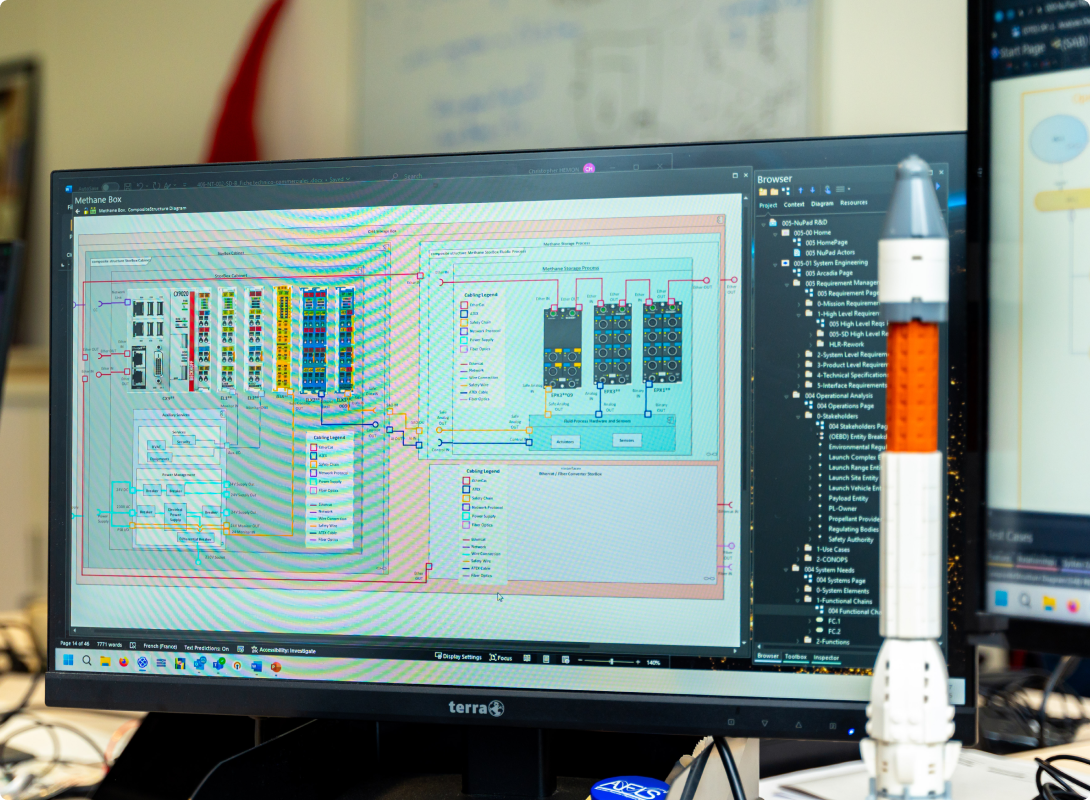

Your Test, Your Box

SpaceDreams provides modular and proven propellant handling systems designed for liquid oxygen, methane, kerosene, and other test fluids.

Rather than starting from scratch, each project builds on a validated technical foundation — including tanks, lines, instrumentation, and control systems — which is then adapted to the specific engine test requirements: pressure, flow rate, automation level, thermal conditions, and safety constraints.

Our systems perform all key functions — filling, draining, cooldown, pressurization, and supervision — with an integrated operating software.

Modules are delivered as off-the-shelf units, configurable as skids, containerized systems, or fixed installations, depending on the test environment.

This approach ensures shorter engineering and commissioning times, while maintaining the flexibility to evolve across different test configurations and propellant types.

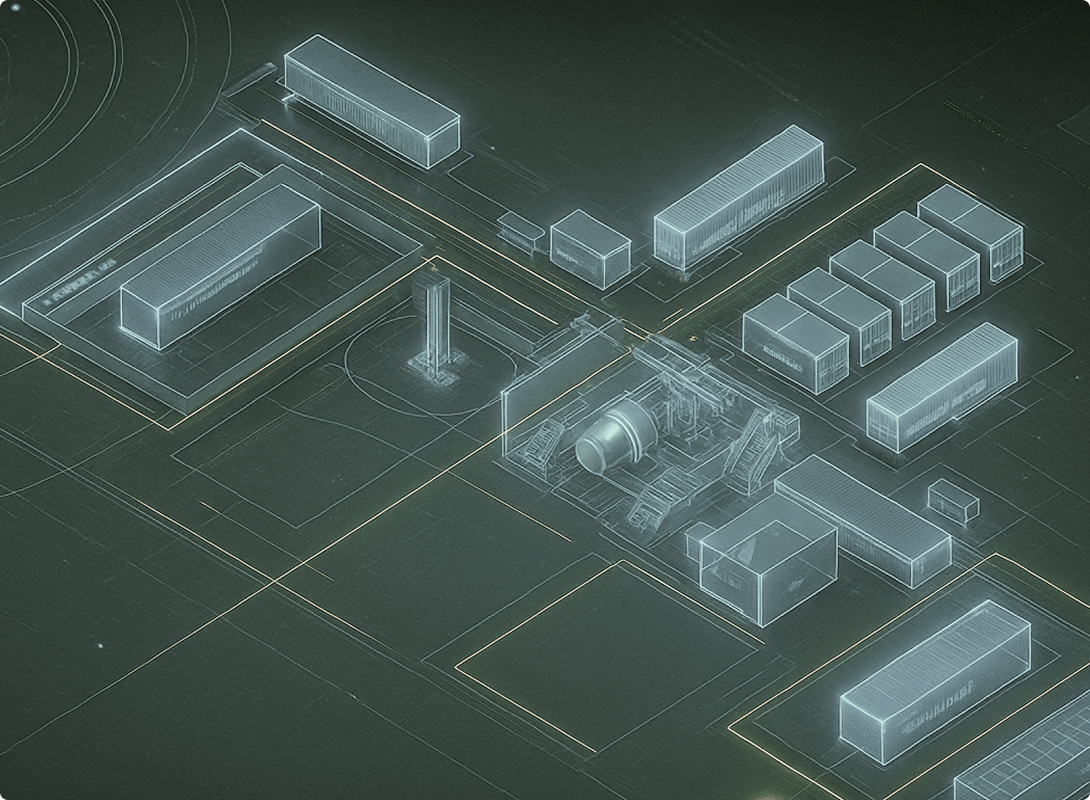

TwinPad

Digital twin integrated

to enhance mission success

The TwinPad combines virtual and real-time operations management for launch complexes, enabling seamless control and monitoring at every stage. It can simulate ground system processes using nearby infrastructure — even if it’s not owned by SpaceDreamS — ensuring full operational flexibility.

SpaceDreams provides modular and proven propellant handling systems designed for liquid oxygen, methane, kerosene, and other test fluids.

Rather than starting from scratch, each project builds on a validated technical foundation — including tanks, lines, instrumentation, and control systems — which is then adapted to the specific engine test requirements: pressure, flow rate, automation level, thermal conditions, and safety constraints.

Our systems perform all key functions — filling, draining, cooldown, pressurization, and supervision — with an integrated operating software.

Modules are delivered as off-the-shelf units, configurable as skids, containerized systems, or fixed installations, depending on the test environment.

This approach ensures shorter engineering and commissioning times, while maintaining the flexibility to evolve across different test configurations and propellant types.