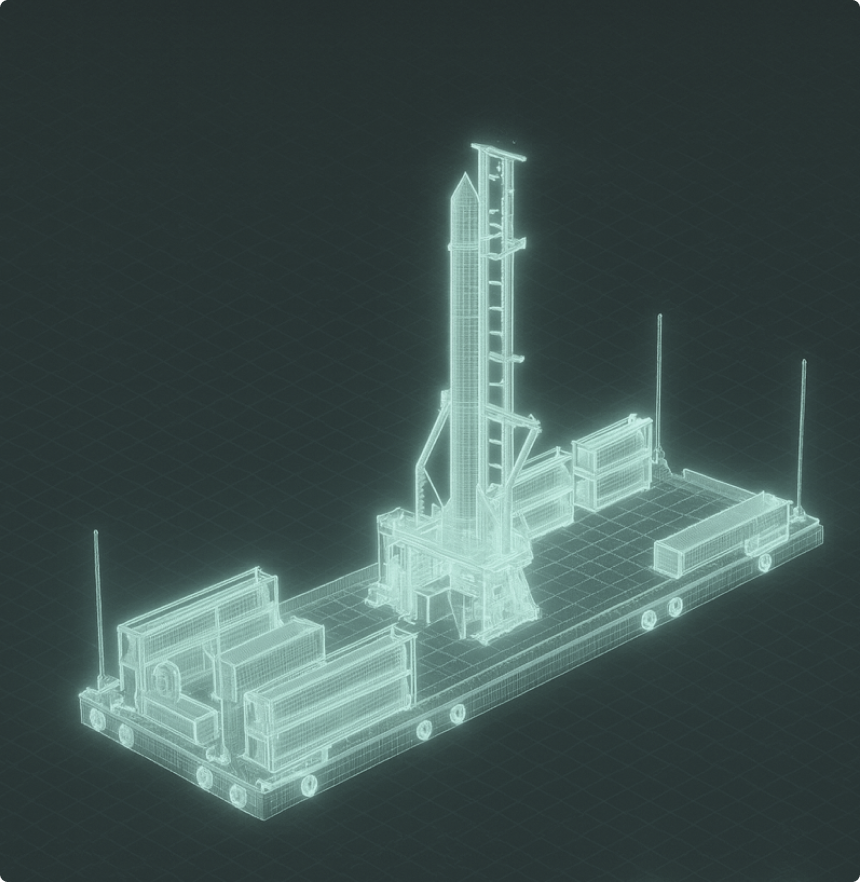

Digital Twin

for Launch Systems

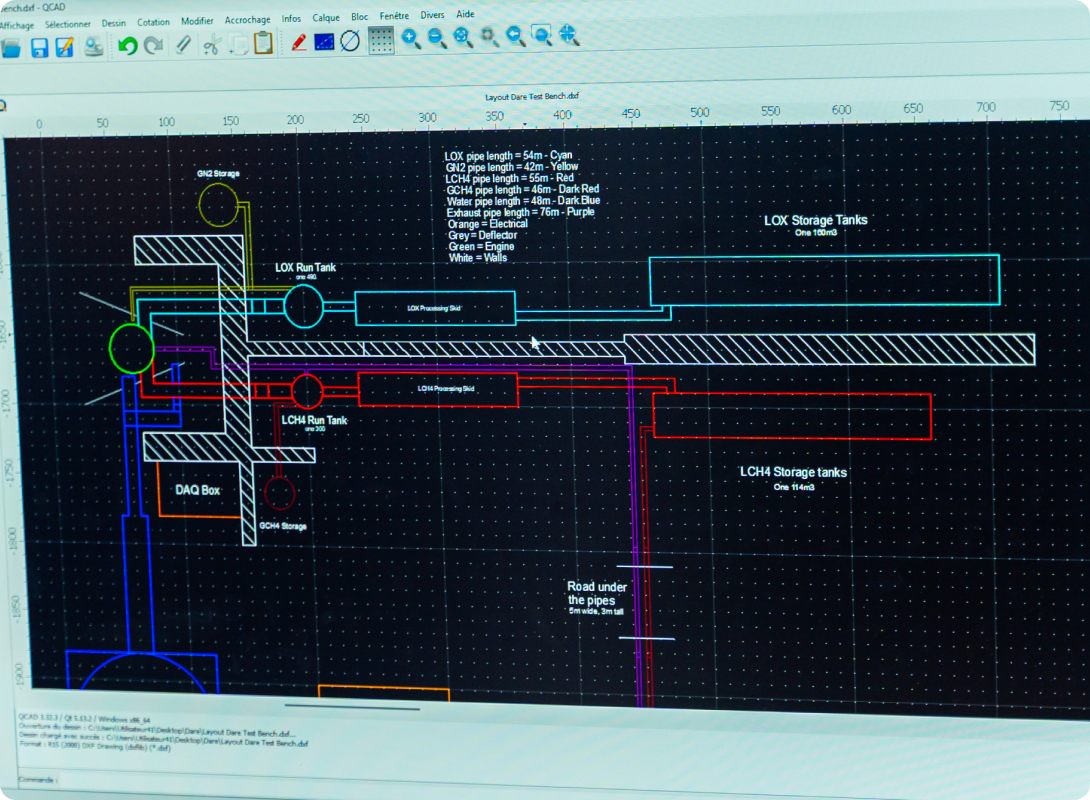

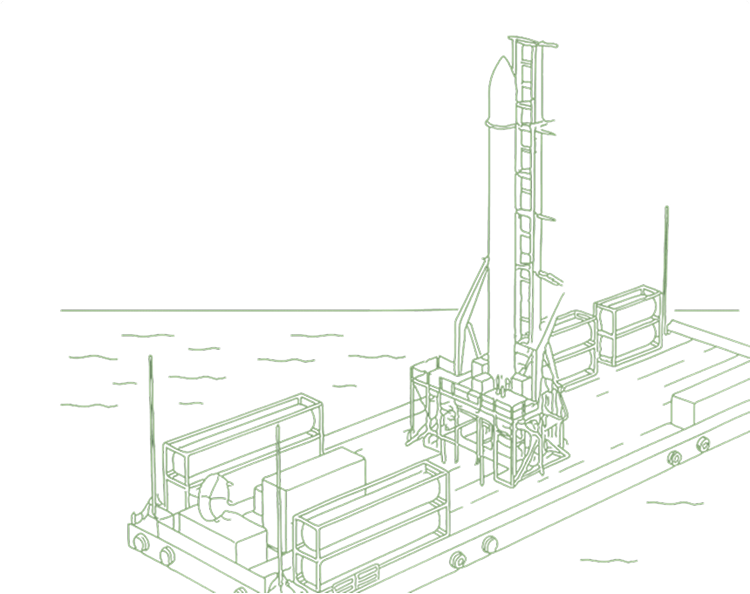

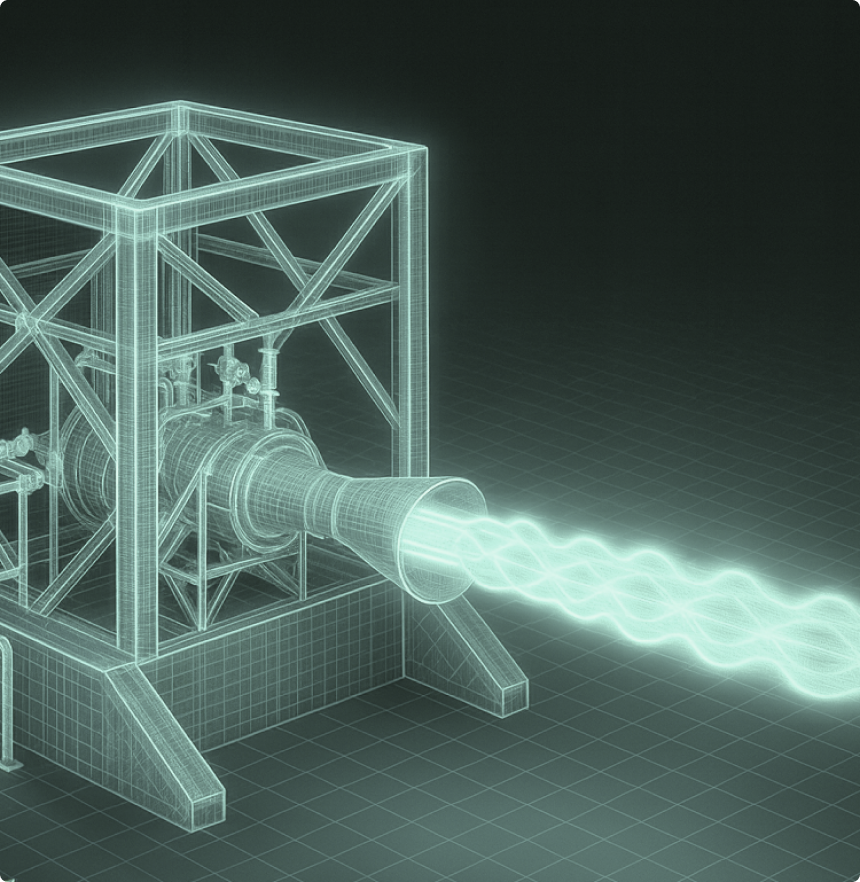

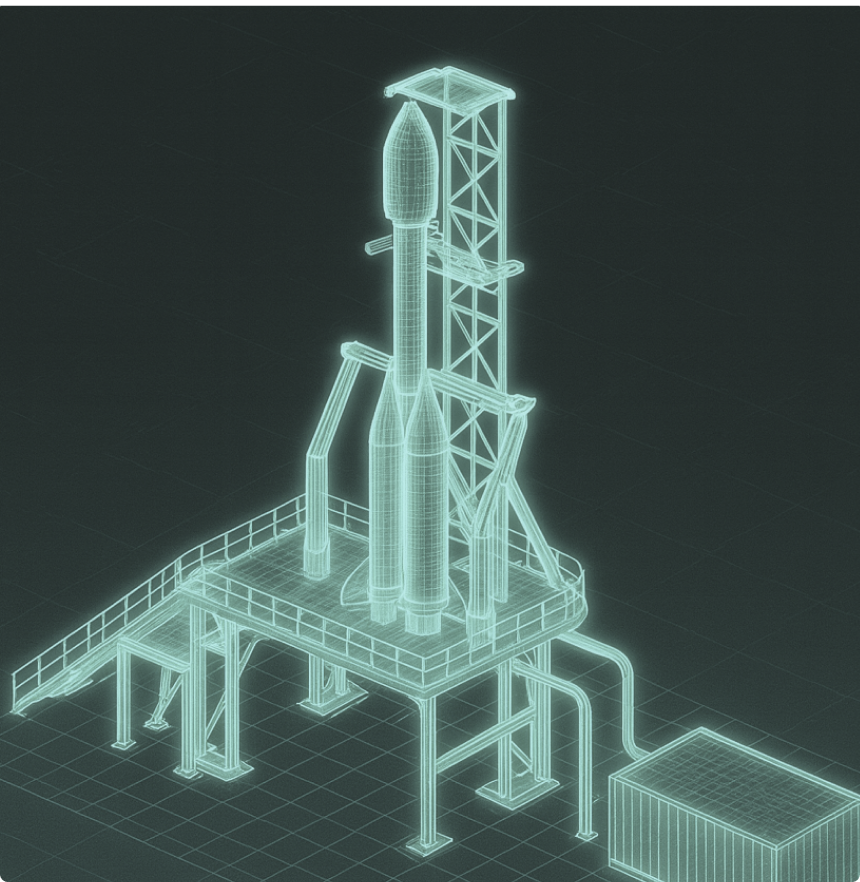

Experience the power of virtual commissioning with TwinPad — the world’s first digital twin of a launch system. It enables end-to-end simulation of the launcher on its pad, merging physical modeling with control-command systems for a hyper-realistic and interactive experience.

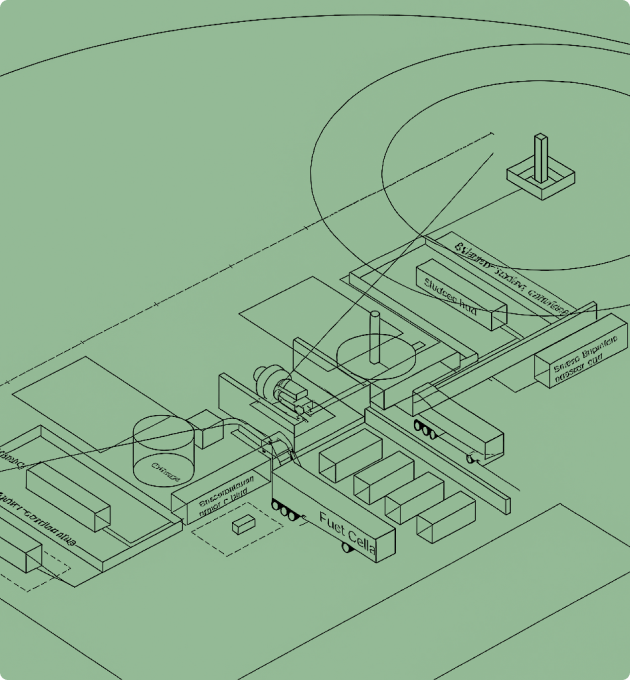

Digital Twin integrated

on each steps

Versatile Across

Lifecycle Stages

TwinPad supports every phase of the mission lifecycle: from conceptual design and software qualification, through user training and configuration management, all the way to ongoing predictive maintenance. Harness its flexibility to optimize operations, training, and system validation.

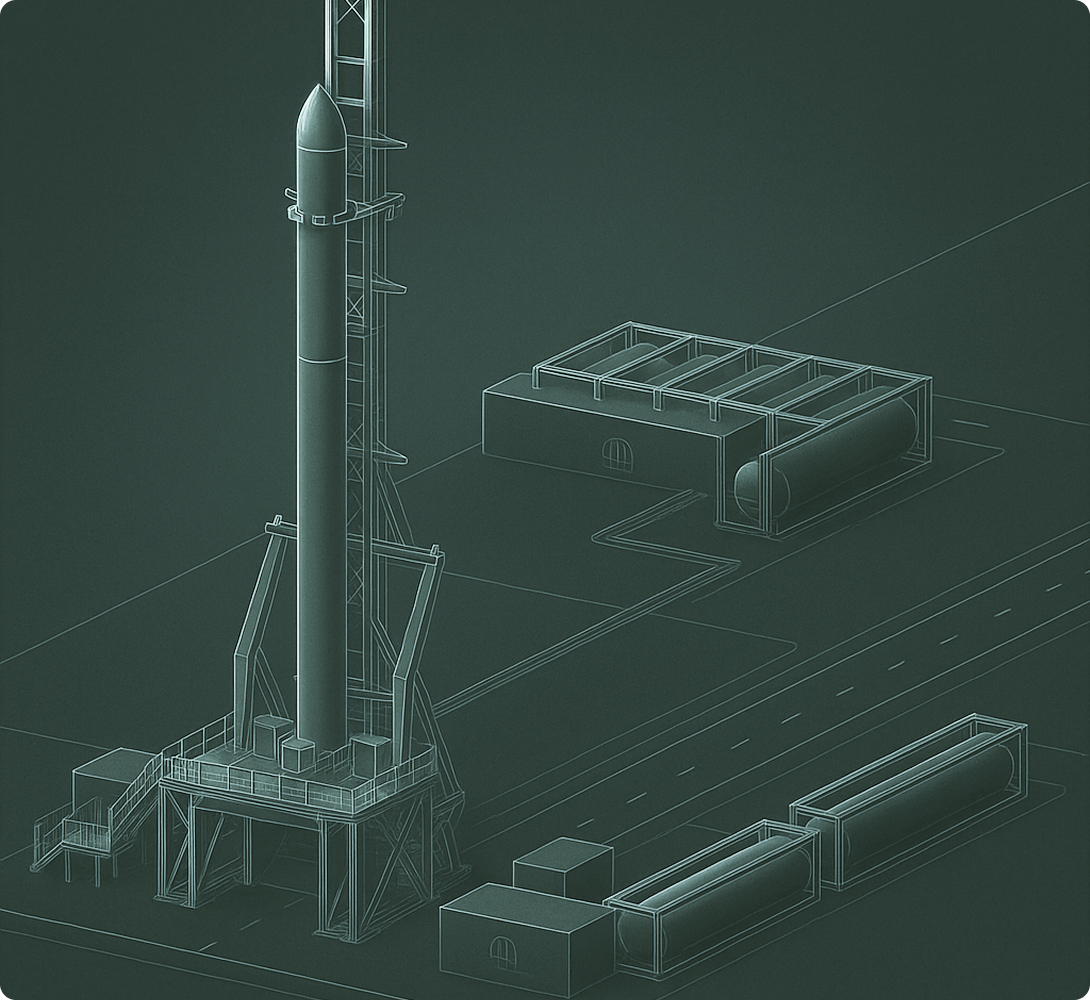

True-to-Life

User Experience

Engage with TwinPad as if you’re operating the actual hardware — the virtual interface is entirely equivalent to reality. This immersive fidelity ensures confidence in testing, lowers training risks, and accelerates development cycles.